What you need for conversion set

- The model and upgrade kit

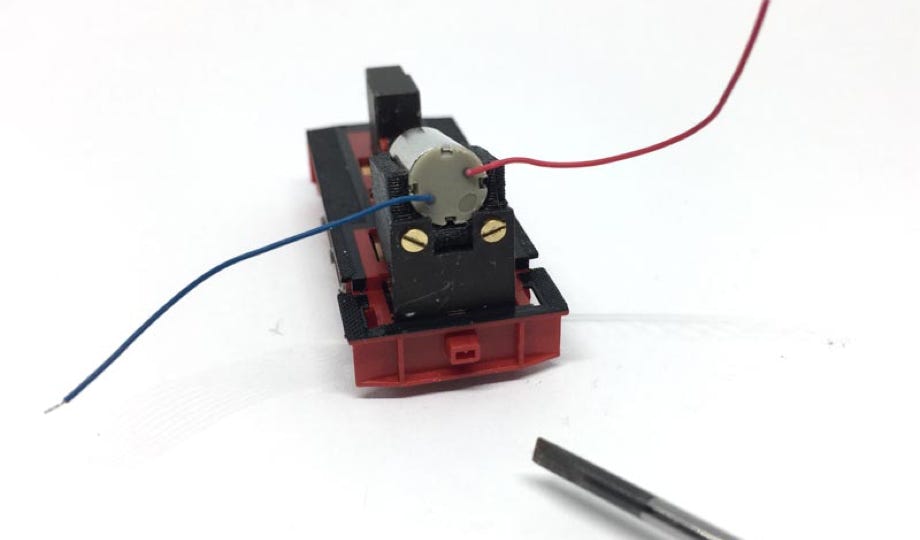

- Small flat screwdriver

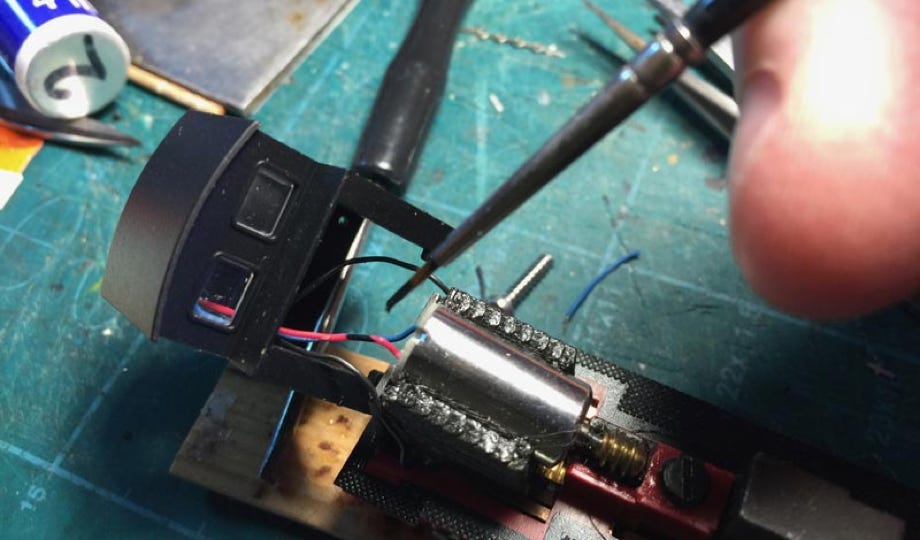

- Soldering iron 15W/25W

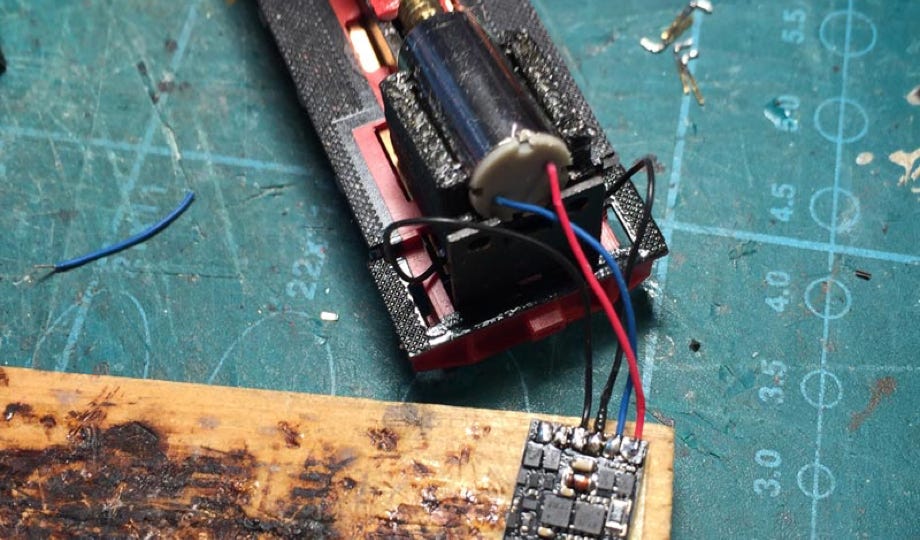

- Thin wire (get the thinnest wire here)

Good to have:

- General modelling tools

Installation time: Around 1 hour

UK based

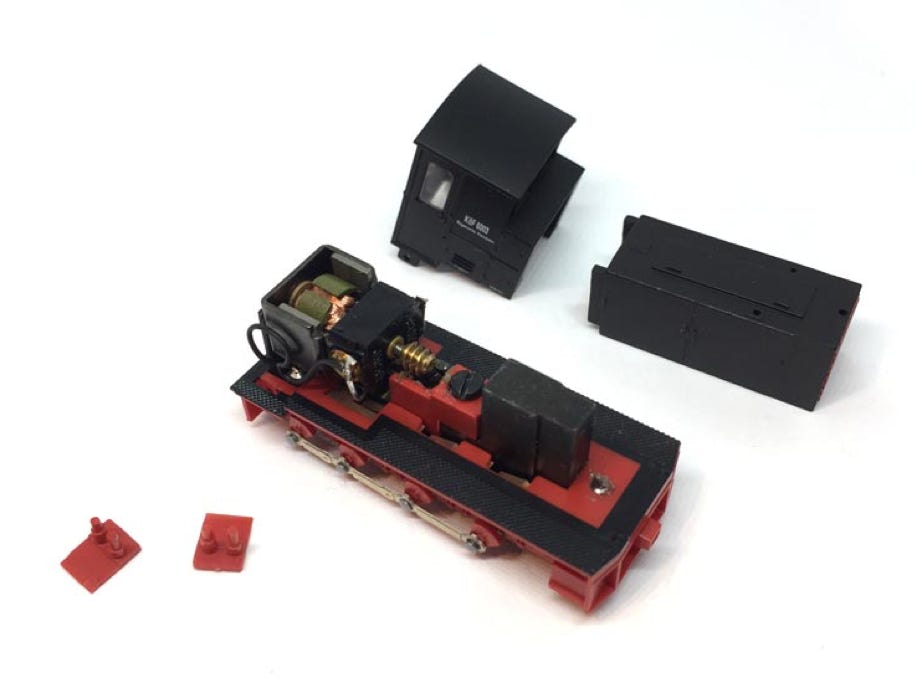

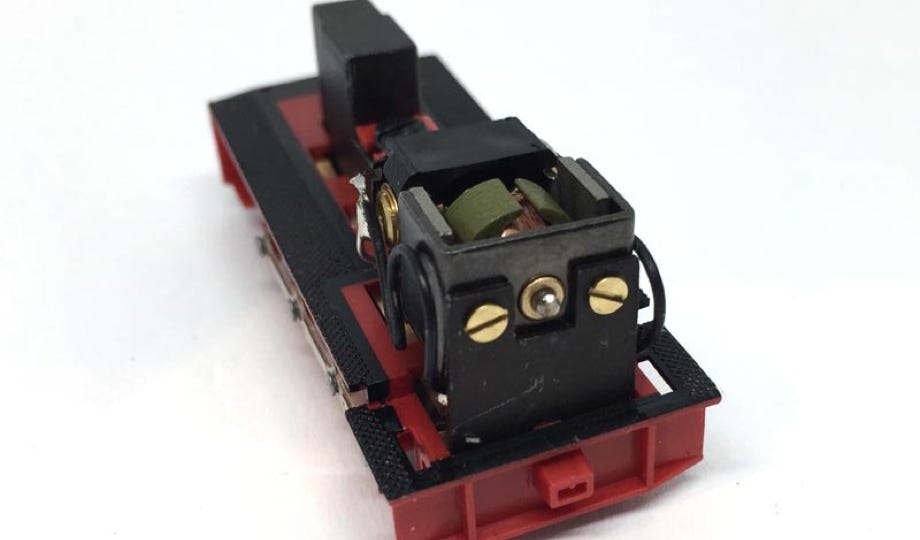

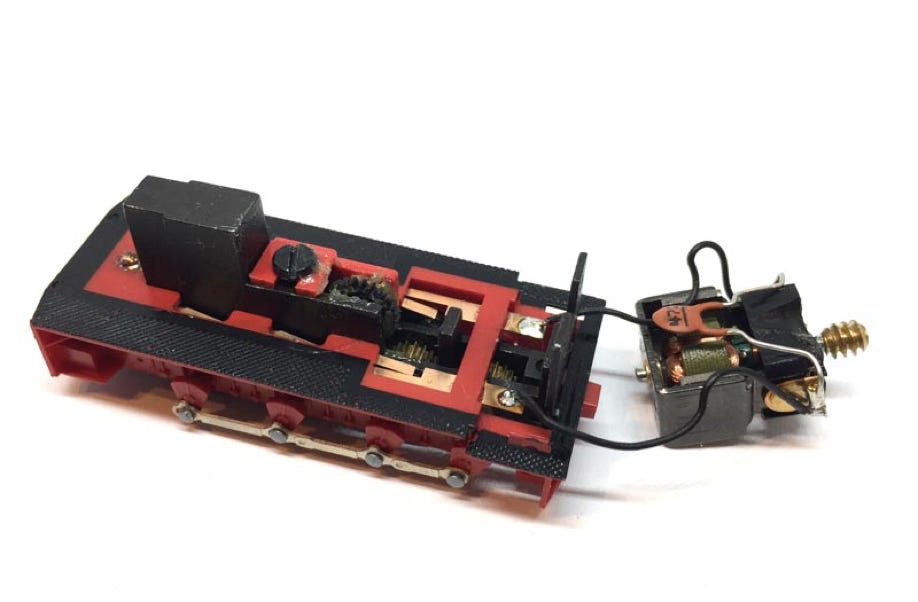

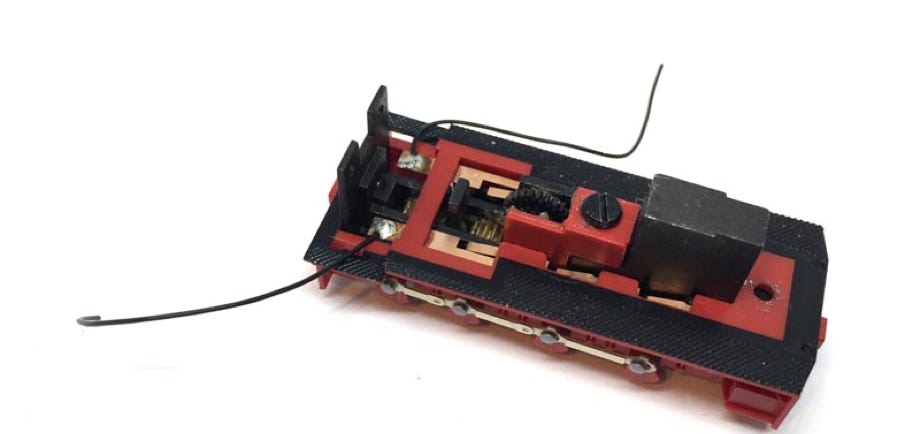

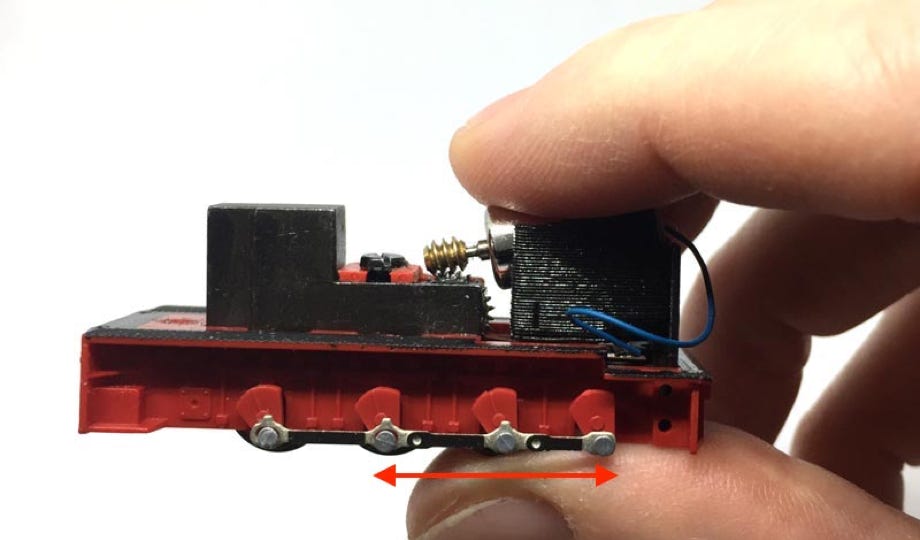

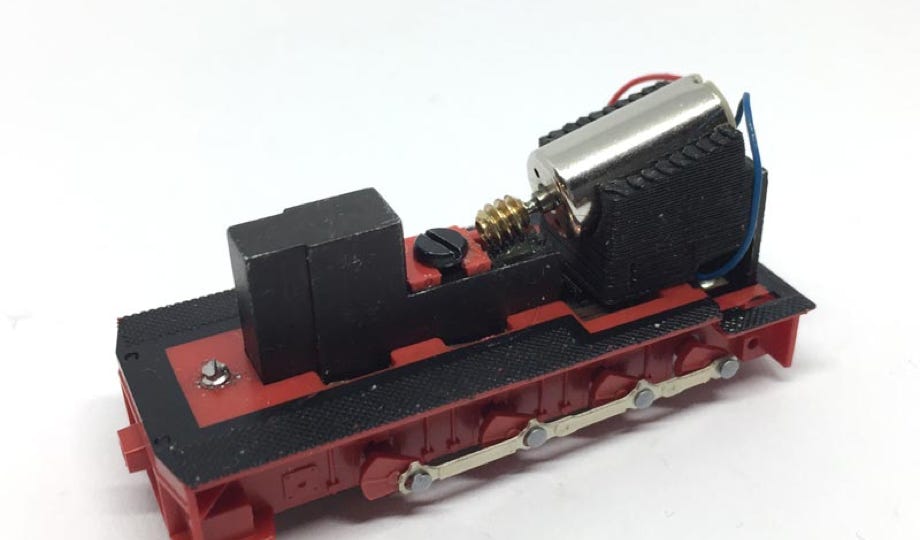

Conversion Bemo HF 130 c/V21/ÖBB 2092

to 12V coreless motor

Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

KASTENLOK INDEX

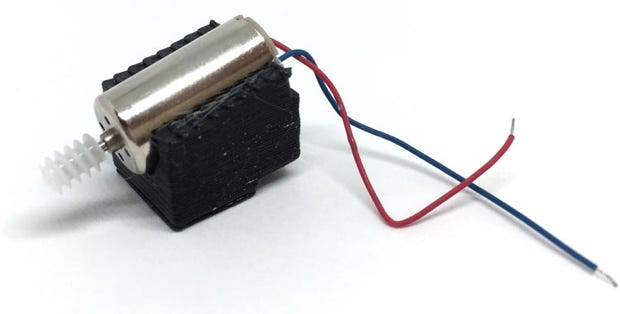

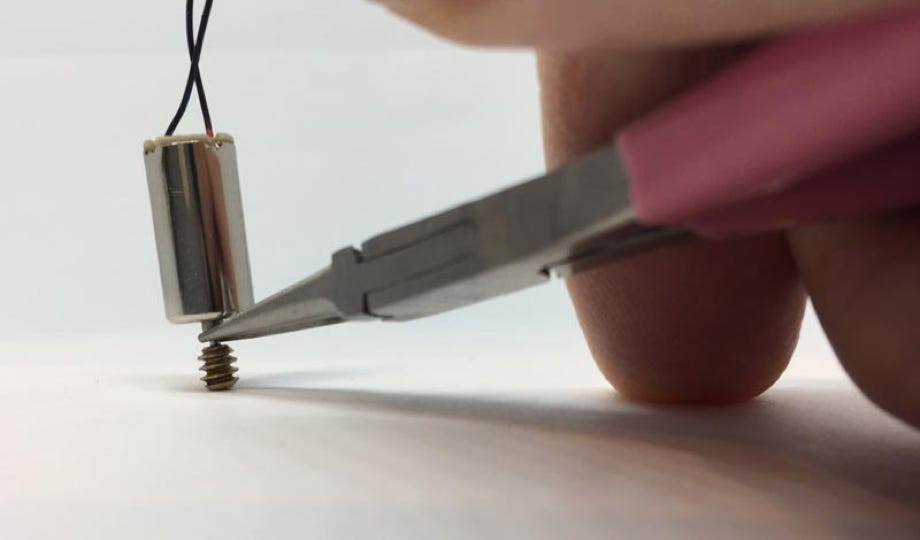

Note: as from mid April 2020, a plastic worm has been supplied with the kit (picture right). This can just be fitted without glue on the motor shaft, so ignore the instructions where it talks about a brass adapter and taking the original worm off.

Question? Just reach out!