UK based

Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

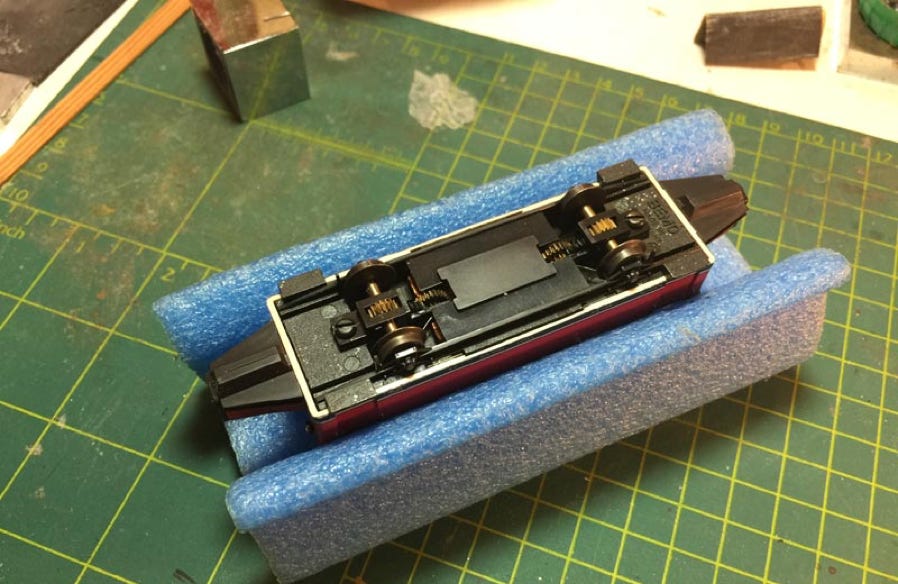

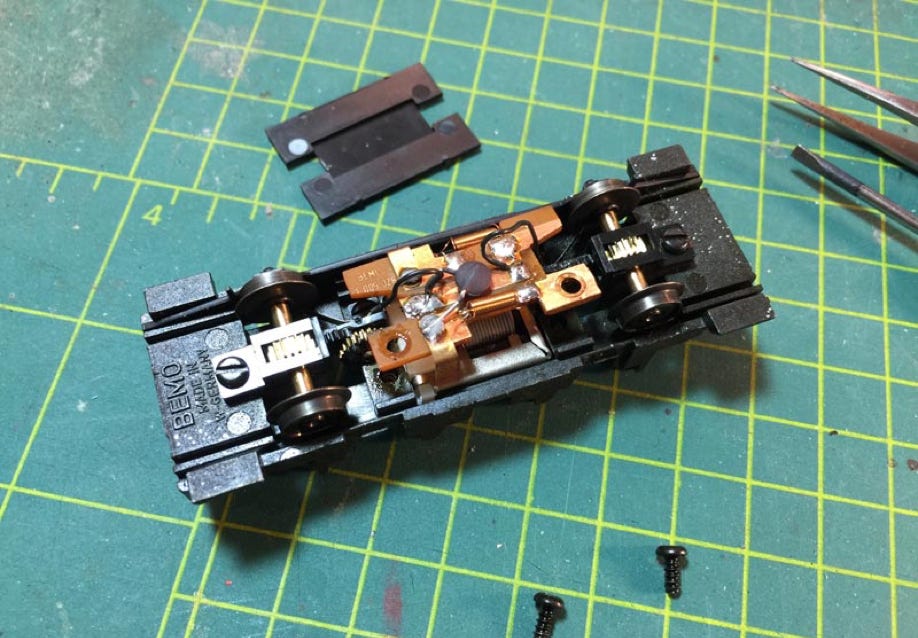

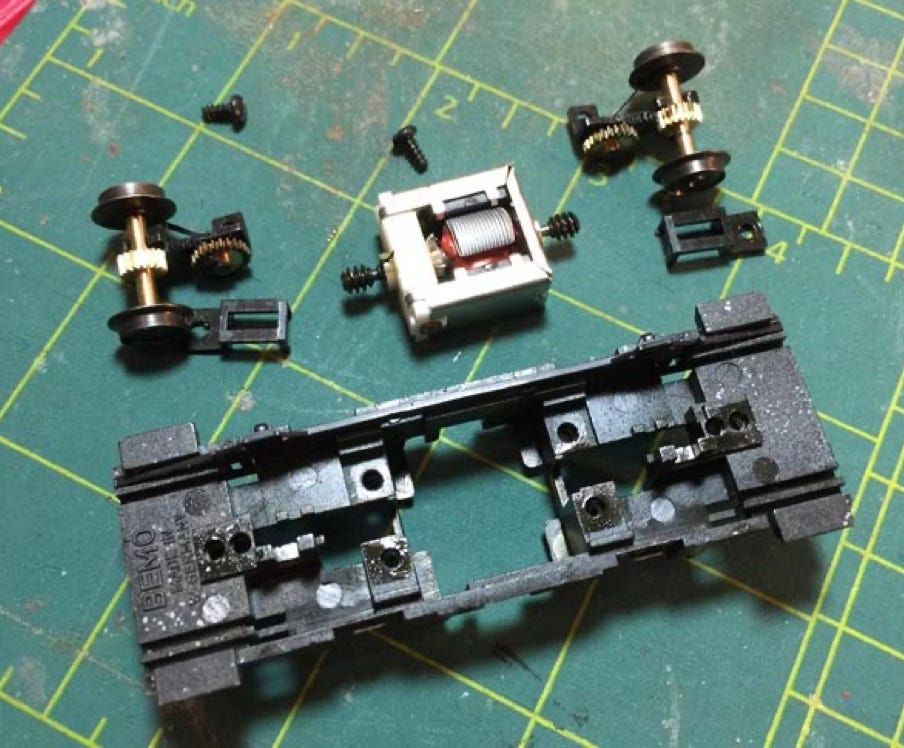

Fits Bemo without flywheel with wheelbase 46.2 mm, Art 1609 906 H0e/H0m and HO.

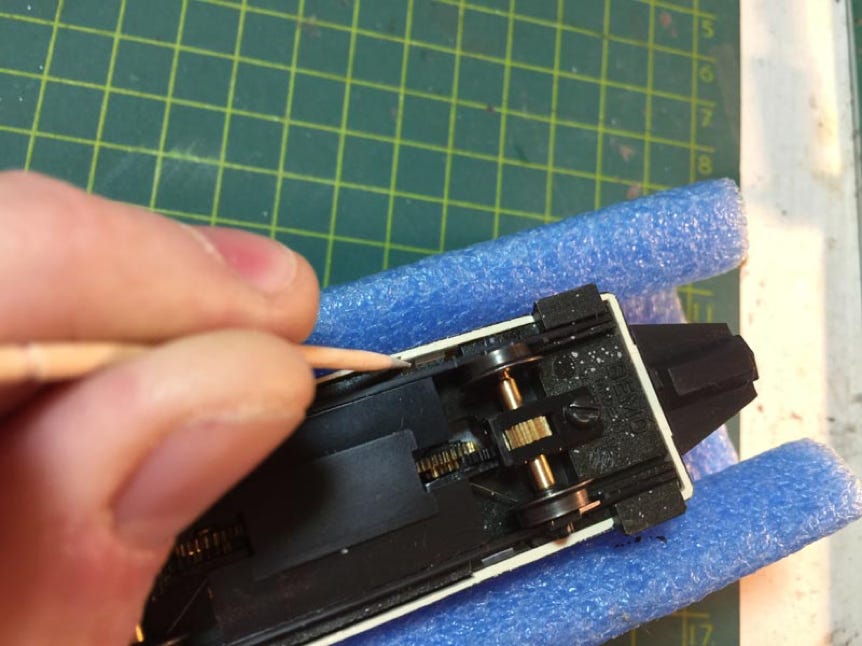

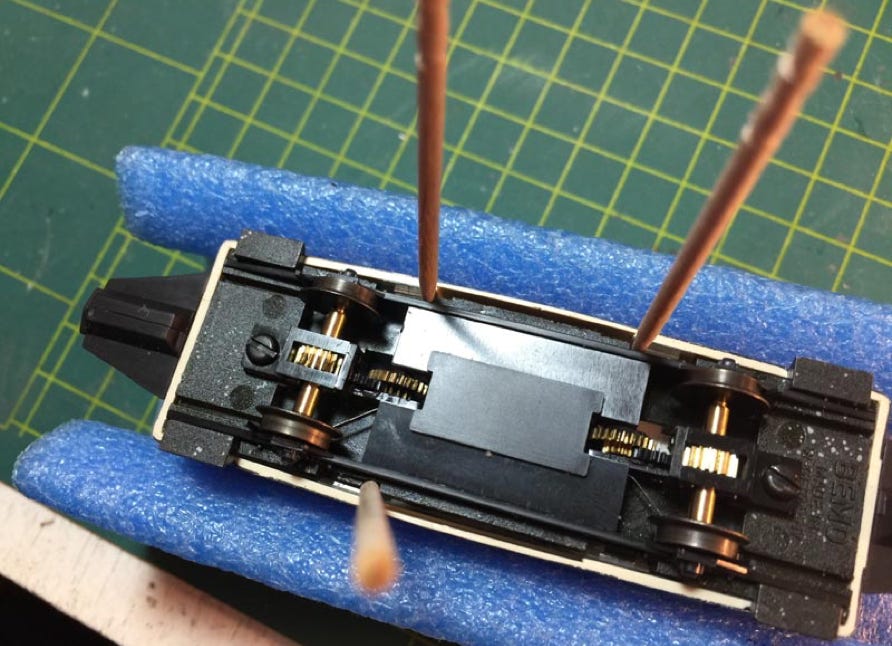

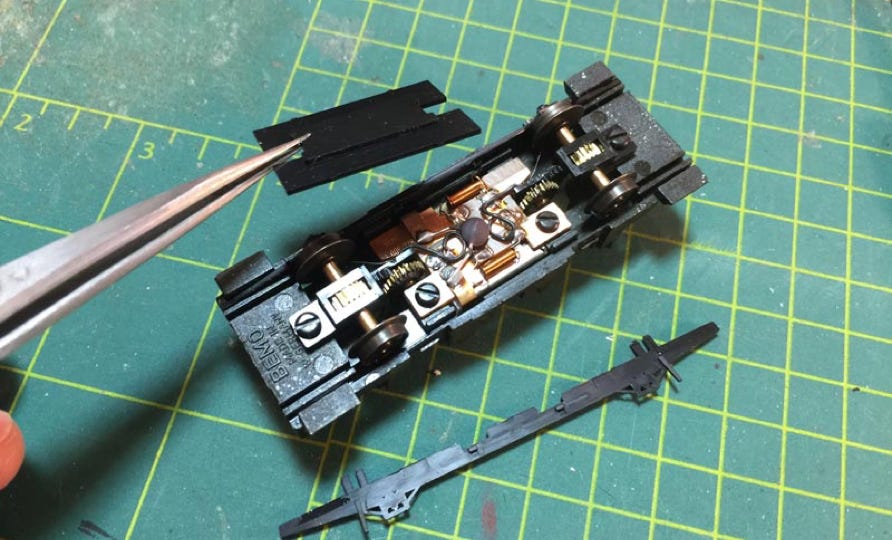

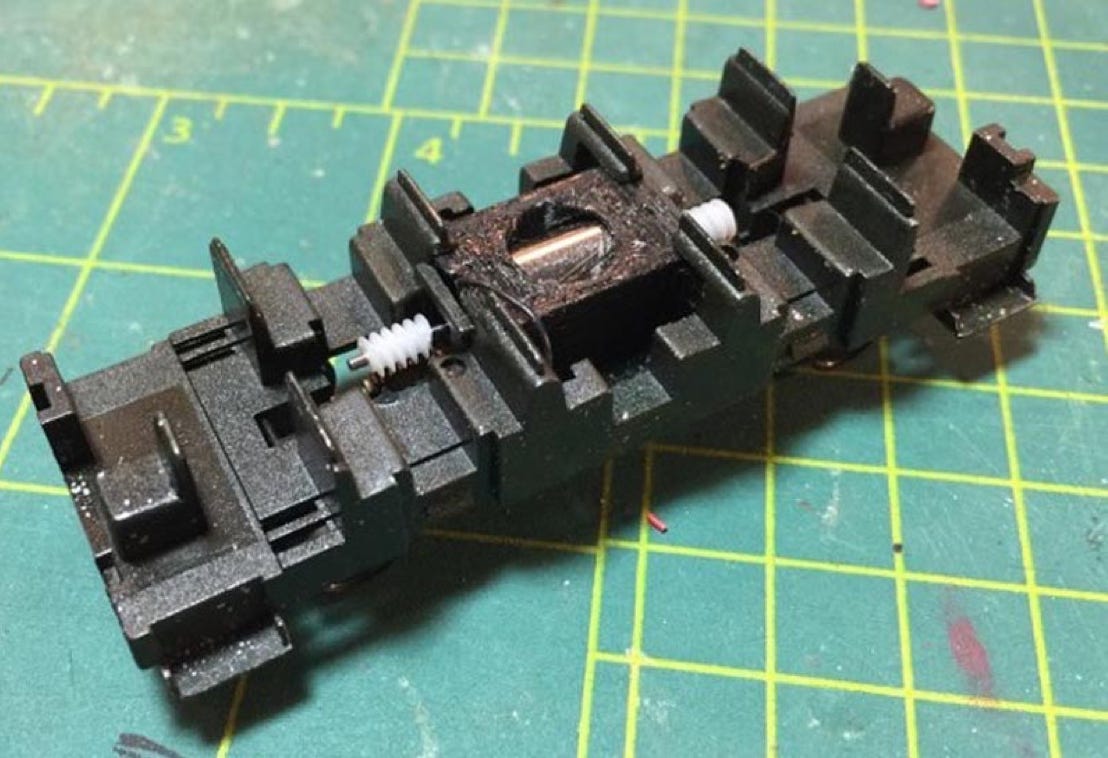

Conversion Bemo Wismar Railbus (older version)

to 12V coreless motor

What you need for conversion set

- The model and upgrade kit

- Small flat screwdriver

- Soldering iron 15W/25W

- Thin wire (get the thinnest wire here)

Good to have:

- General modelling tools

Installation time: Around 45 minutes

Art. BE1006-1

Contents of the kit

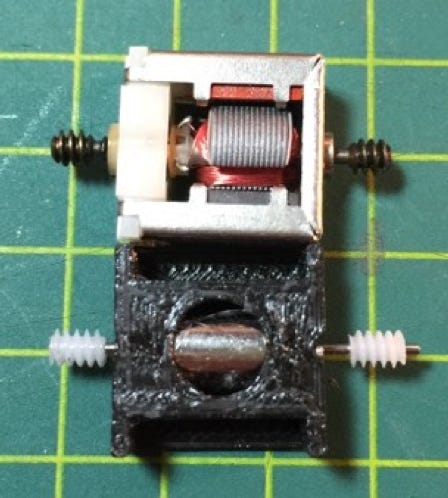

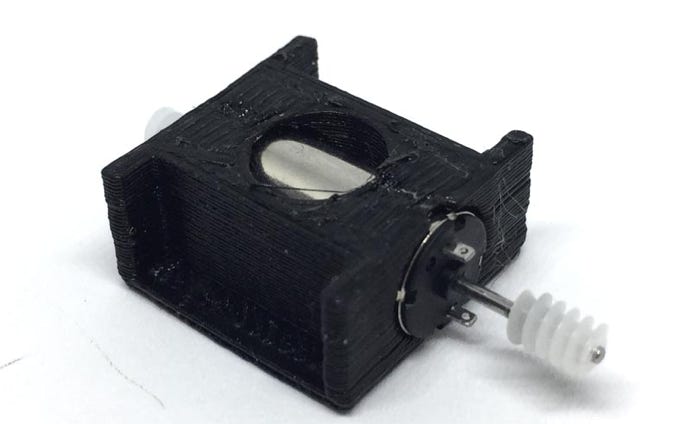

1x 8x16 mm motor

1x motor casing

2x M0.3 worm