What you need for conversion set

- The model and upgrade kit

- Small flat screwdriver

- Soldering iron 15W/25W

- Thin wire (get the best wire here)

- Epoxy glue

- Super glue

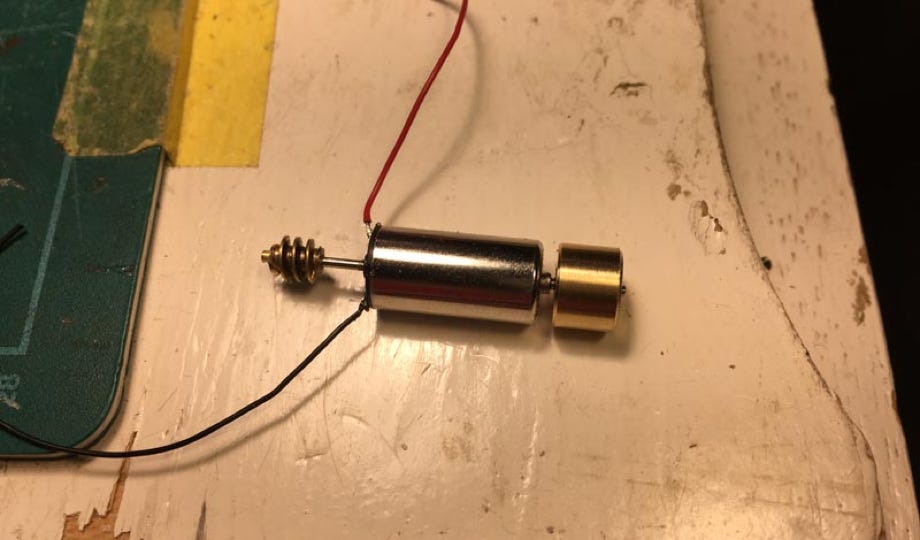

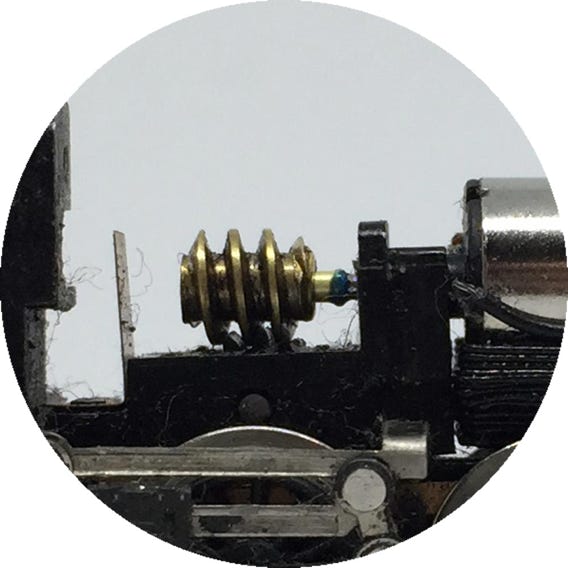

Replacement worm included!

Installation time: <1 hour

1

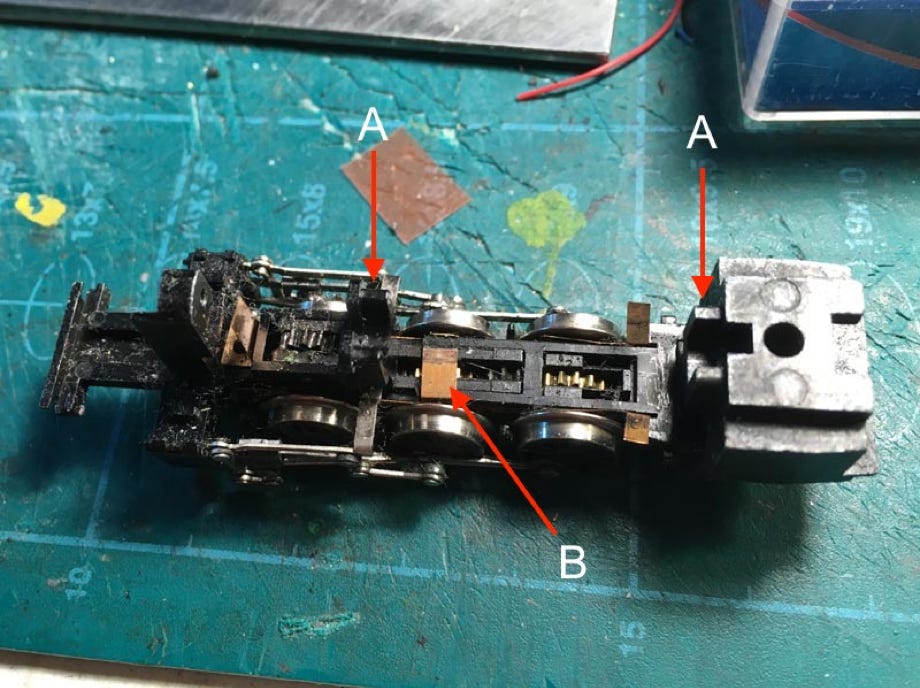

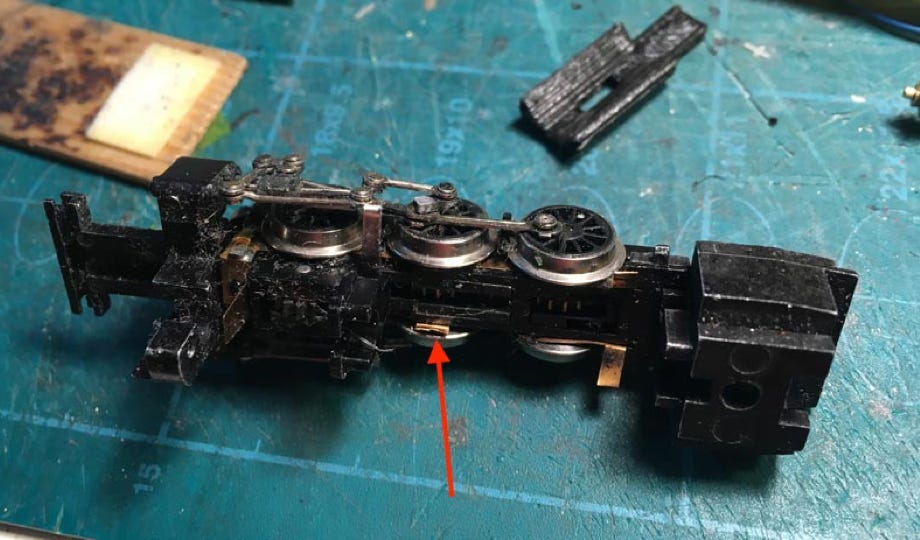

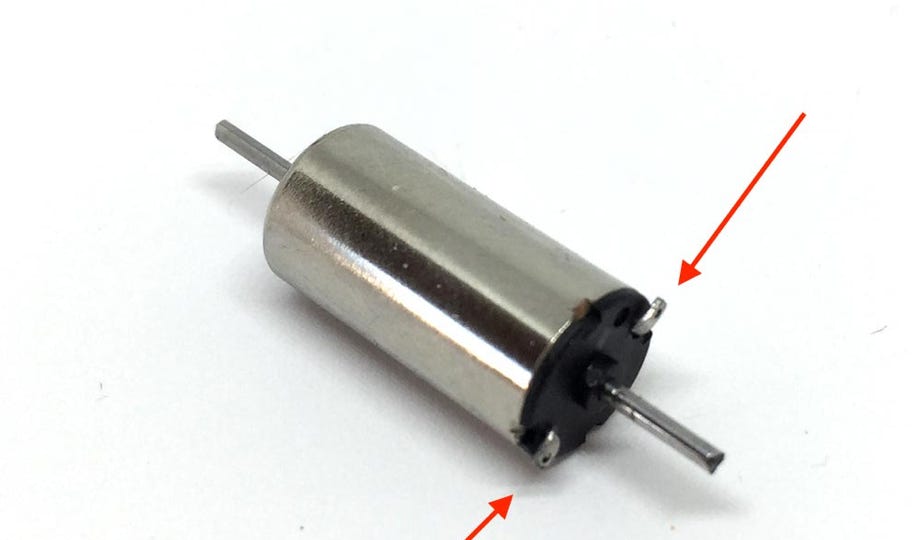

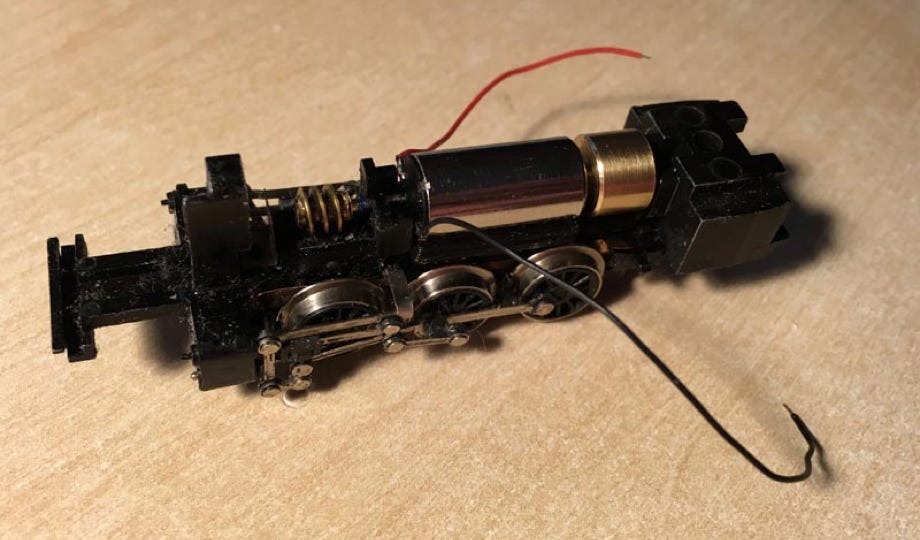

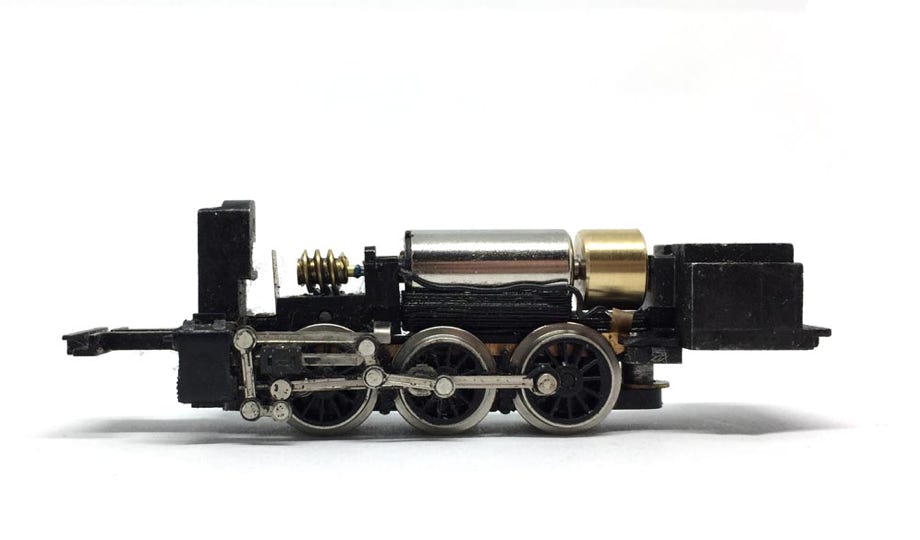

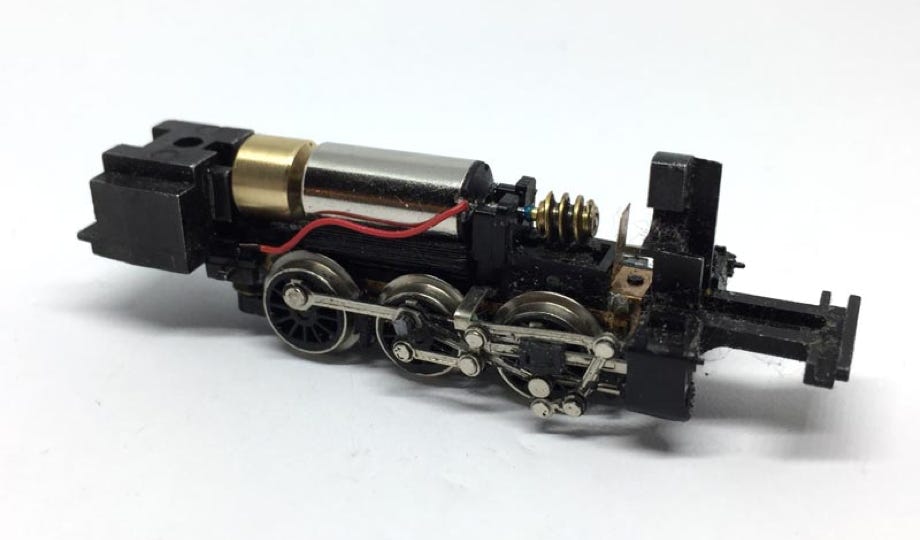

to coreless motor

UK based

For Minitrix article numbers 2028, 2029, 2030, 2039, 2040, 11415, 12027, 12028, 12038, 12039, 12040, 12836, 12839 among others.

See and hear the remarkable difference between the original and the new motor.

Take apart

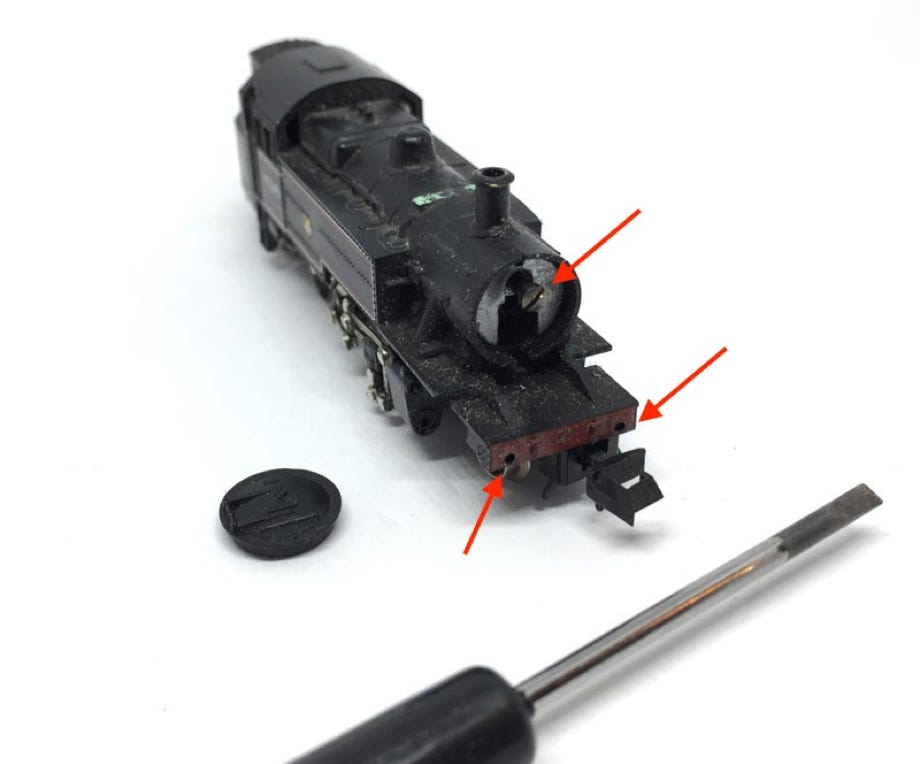

Remove four buffers (front and rear) by pulling them. Take the boiler door out by putting your nail behind it and pull it out. Remove the screw and the cover comes off.

Conversion Minitrix Ivatt/BR 24/BR 64

Question? Just reach out!