What is wrong with the

Heljan Manning Wardle?

Well, a lot is wrong with it, as it appears. The Manning Wardle was highly anticipated, after the announcement Heljan would be releasing this as a 009 model. Unfortunately, the models have many, many problems, which makes it hard to enjoy it. Most models will have been resold or shelved, as they couldn’t manage just light curves, but they also derailed very often when going over points. Some issues can be fixed, but to fix all issues, the odds are against us from the start.

Does not handle curves

Its main problem and the root of all evil: It can’t manage curves. Only the slightest of curves, but failing at normal curves where other models manage easily. When you see why, you scratch your head. Have the engineers at Heljan tested this model at all on a curve? Was the thinking that in real life they don’t go through curves of any meaning, so the model doesn’t either? Accuracy to the prototype seems to have had priority over play value. We are off to a bad start, as it is not something that can be solved, without cutting parts out of the model.

Even though the engineers made as much space as they could get, by thinning the side boards, it is not anywhere near enough.

Solution: cut the side boards.

This will create a gaping hole when seen from the side and expose the wheels.

Alternatively, you can mill the flang from the wheels, so the wheels float, but it will always be ugly, ugly, ugly.

Wheels too light and fitted too tight

The wheel float, the don’t always roll. The wheels are plastic on the inside and seem to have a metal rim, which makes them very light. On top of that, they are clipped too tightly.

Solution: Replace with 8mm wheels and brass rod ID 1.5 OD 2.5 mm. See replacement instructions here.

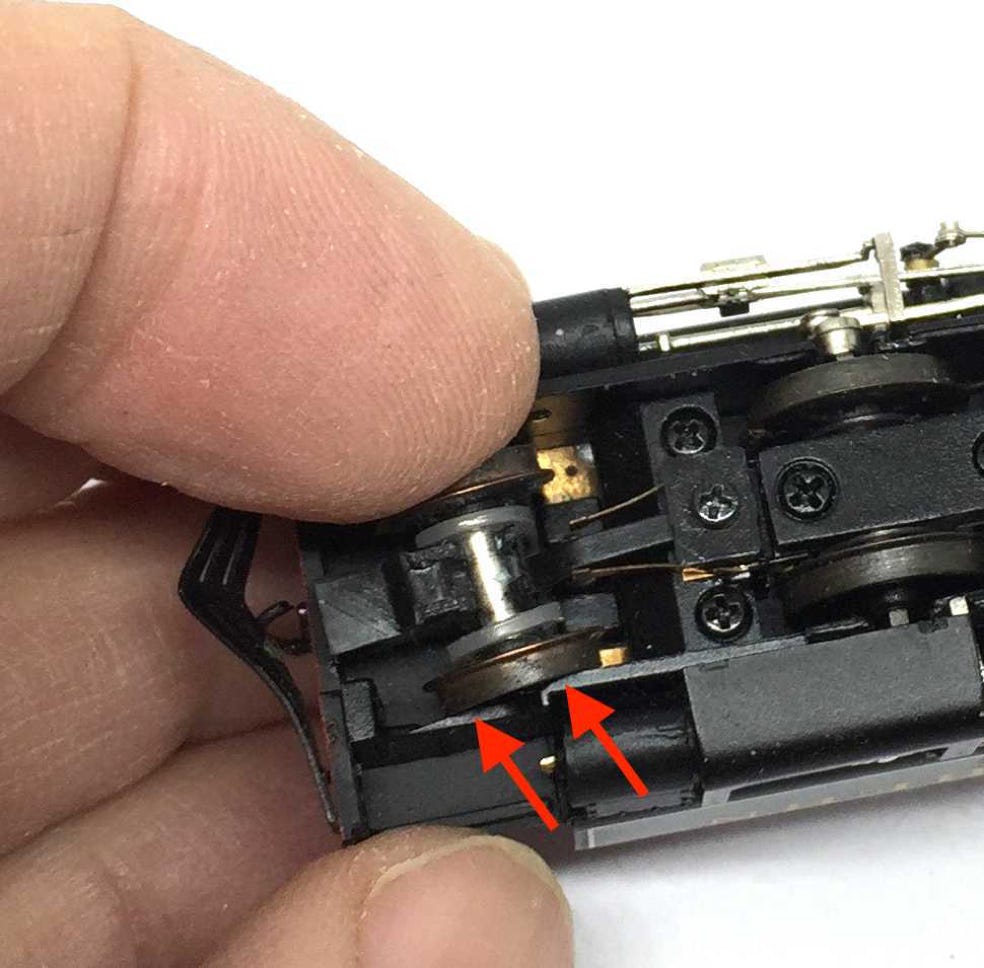

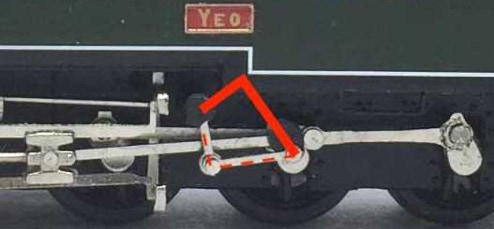

Reversed valve gear

When turning the model upside down and depending of the position of the Valve gear, the “elbow” is upwards. The model will stall and pushes out the pin of the front driving wheels.

Solution: Make sure you check for this, after each inspection when you want to run the model.

Valve gear pin falls out

The pin to the at the front driving wheels comes out

It seems to happen when you get the “reversed elbow” issue. Of course, a pin like that will be very hard to find again.

Solution: Use a short M1.0 screw and cut it off at end. You can then screw it in with a small screw driver.

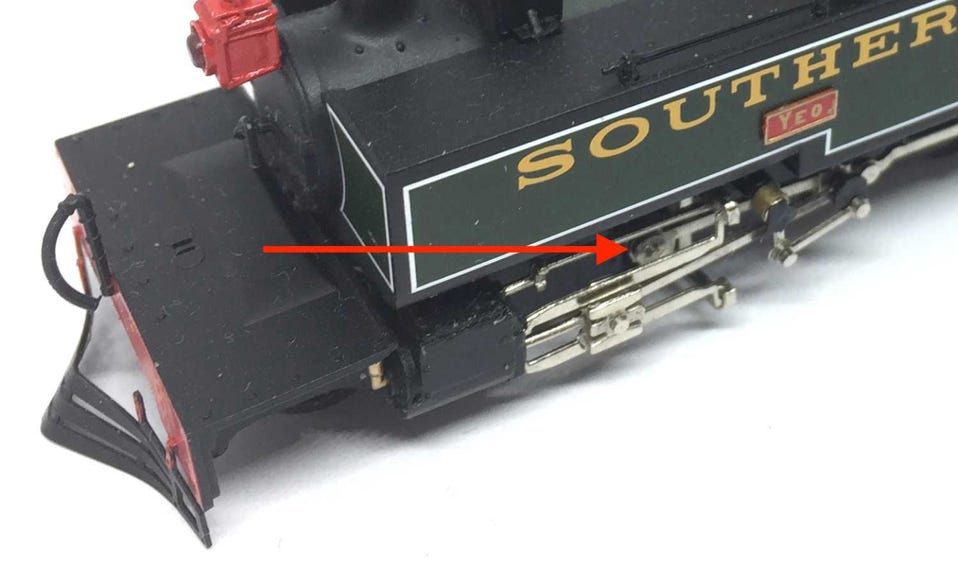

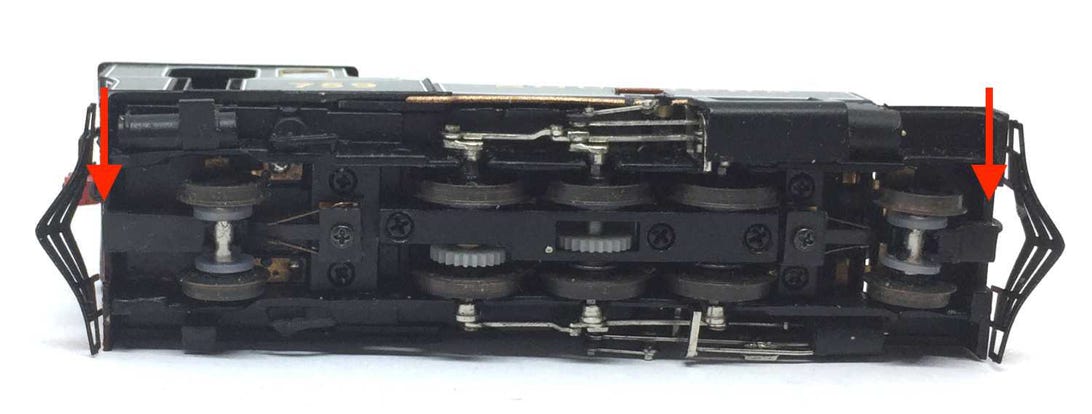

Couplings lift housing up

I don’t know what I find the dumbest design. This one is a major contender as well. The NEM shafts of the couplings on both sides are extended until under the front board. Now the bogies don’t have play upwards, so the pony wheels keep the six driving wheels floating. The model can’t drive.

Solution: Cut 1mm of each end of the couplings or replace the couplings by a 3D printed one (read on for that).

Coupling and cow catcher can’t both be installed

In real life, the couplings are fitted to the red front board. But in model to the pony trucks. This is not a design flaw, but a choice by Heljan. I guess they were limited by the wish to have NEM coupling pockets. I can imagine the desire to have them attached to the pony trucks, as you would be enable to go through tighter curves, because the couplings pivot with the curves. Ha! As we’ve seen the pony trucks can’t move far enough for those curves. Heljan could have saved themselves the trouble and fitted the coupling on the front board. I don’t know what they were thinking, as when you fit the cow catchers, even if it is for display, you still want to see couplings. Not a gaping hole.

So let me solve that for Heljan.

Possible solution: By redesigning the coupling side of the pony truck, a metal coupling can be inserted (A purpose made coupling, Greenwich folding style). The coupling is fixed with a small screw. It is even possible to add a phosphor bronze strip if pressure on the pony truck is desired, but when using metal wheels, it seems not needed.

To be clear, this is not something I sell at the moment and for the time being, there are no plans to do so. I suggest to create your own version using Greenwich couplings.

Front wheel is not geared

Another objection I have to the model is that the front wheel is not geared, but driven by coupling rod. I know it does work for other models, but I’m not a big fan of it. Better to have all driving wheels geared, so it is not putting any pressure on the outside motion.

Conclusion

I only bought two of these models out of interest of the problems that I heard about it. I am not an unhappy customer, but a curious “micro engineer”. I would not advise anyone to purchase them new for the full price. They are good for display or straight layouts without any curve nor point. If you would like one, despite its problems, it won’t be hard to find one second hand. As what ever negative can be said about the model, it’s still very pretty.

Hope this contribution helps anyone understanding the issues with the model.

•